Week 9: Input Devices

This week, I decided to move from Windows

to OS since there's more knowledge in the community about AVR

programming in OS than in Windows.

First of all, I redid the assignment from Week 7 on the Mac in the

lab. I successfully programmed the board and managed to make the

LED blinking.

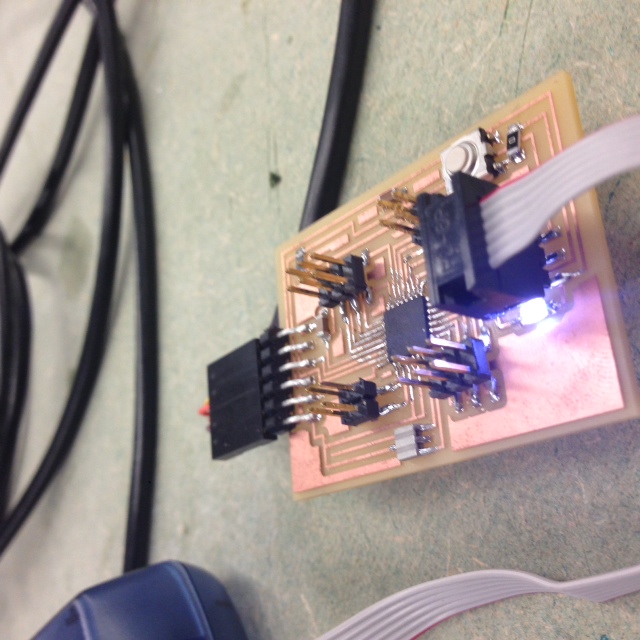

Then, I tried to experiment with the phototransistor for this

week's assignment.

I used those board traces

and interior

to mill the board. Then, I used the c

code and makefile.

The programming was successful as terminal returned below

messages:

PHYS-LAB-24:desktop

physicslab24$ avrdude -p t45 -c avrisp2

^[[A

avrdude: AVR device initialized and ready

to accept instructions

Reading | ##################################################

| 100% 0.00s

avrdude: Device signature = 0x1e9207

avrdude: Expected signature for ATtiny45 is

1E 92 06

Double check chip, or use -F to override this check.

avrdude done. Thank you.

PHYS-LAB-24:desktop physicslab24$ avrdude

-p t44 -c avrisp2

avrdude: AVR device initialized and ready

to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e9207

avrdude: safemode: Fuses OK (H:FF, E:DF,

L:7E)

avrdude done. Thank you.

PHYS-LAB-24:desktop physicslab24$ avrdude

-p t45 -c avrisp2

avrdude: AVR device initialized and ready

to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e9206

avrdude: safemode: Fuses OK (H:FF, E:DF,

L:62)

avrdude done. Thank you.

PHYS-LAB-24:desktop physicslab24$ make -f

hello.light.45.make

avr-objcopy -O ihex hello.light.45.out

hello.light.45.c.hex;\

avr-size --mcu=attiny45 --format=avr

hello.light.45.out

AVR Memory Usage

----------------

Device: attiny45

Program: 502 bytes

(12.3% Full)

(.text + .data + .bootloader)

Data:

1 bytes (0.4% Full)

(.data + .bss + .noinit)

PHYS-LAB-24:desktop physicslab24$ make -f

hello.light.45.make program-avrisp2

avr-objcopy -O ihex hello.light.45.out

hello.light.45.c.hex;\

avr-size --mcu=attiny45 --format=avr

hello.light.45.out

AVR Memory Usage

----------------

Device: attiny45

Program: 502 bytes

(12.3% Full)

(.text + .data + .bootloader)

Data:

1 bytes (0.4% Full)

(.data + .bss + .noinit)

avrdude -p t45 -P usb -c avrisp2 -U

flash:w:hello.light.45.c.hex

avrdude: AVR device initialized and ready

to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e9206

avrdude: NOTE: "flash" memory has been

specified, an erase cycle will be performed

To disable this feature, specify the -D option.

avrdude: erasing chip

avrdude: reading input file

"hello.light.45.c.hex"

avrdude: input file hello.light.45.c.hex

auto detected as Intel Hex

avrdude: writing flash (502 bytes):

Writing | ################################################## | 100% 0.17s

avrdude: 502 bytes of flash written

avrdude: verifying flash memory against

hello.light.45.c.hex:

avrdude: load data flash data from input

file hello.light.45.c.hex:

avrdude: input file hello.light.45.c.hex

auto detected as Intel Hex

avrdude: input file hello.light.45.c.hex

contains 502 bytes

avrdude: reading on-chip flash data:

Reading | ################################################## | 100% 0.16s

avrdude: verifying ...

avrdude: 502 bytes of flash verified

avrdude: safemode: Fuses OK (H:FF, E:DF,

L:62)

avrdude done. Thank you.

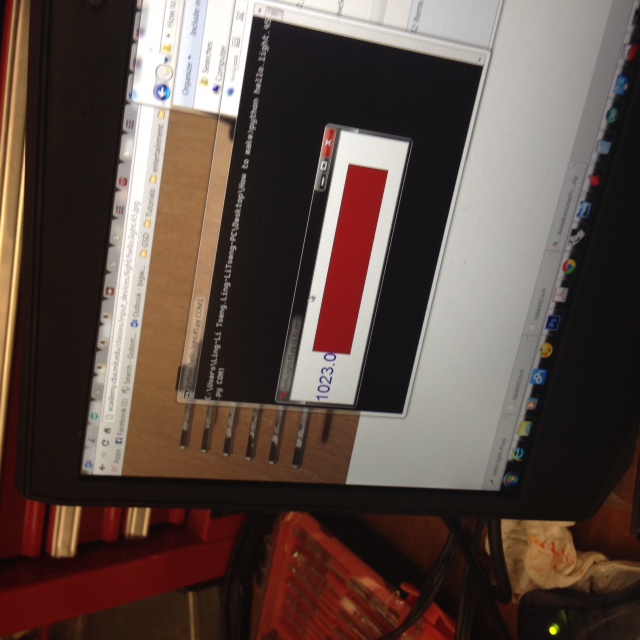

Then, I downloaded the python

file, identified USB port on my laptop, and managed to do a

testing for the measurement.

The meter showed up but the reading didn't move with the change of

light. I suspect it's because the sensor wasn't properly soldered

on the board. I'll look into it further.

A few issues that I ran into and solutions:

(1) Lab computer did not recognize FTDI as a USB port. I changed

to a PC and read the port from device manager. Then I ran

the python program on PC.

(2) Make sure you always load setting in fab module before milling

otherwise you might ran into errors.

(3) If you cannot cut through the board, check if you put the

endmill too high when you zero it and z axis doesn't have enough

space to further go down.

(4) If you have an even milling results on the board, make sure

your taps behind the board are flat: no overlapping and no heads.